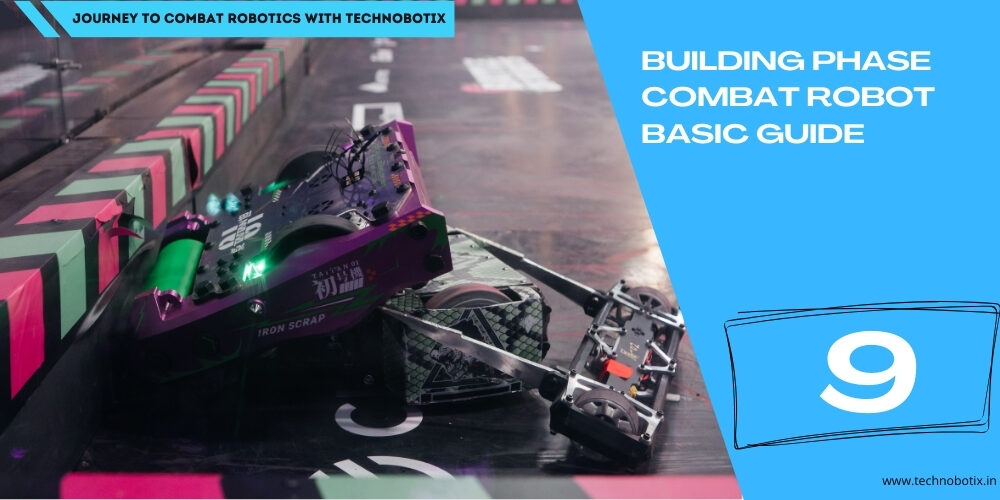

Build Your Combat Robot

Building a combat robot requires careful attention to detail and quality craftsmanship to ensure a robust and reliable final product. Here’s a breakdown of the construction process into manageable steps:

- Assembling the Chassis:

– Start by gathering all the necessary materials and components for the chassis, including frame materials (e.g., aluminum, steel, or composite), fasteners, and tools.

– Follow the design plans and CAD models to cut, drill, and assemble the chassis components according to the specified dimensions and configurations.

– Pay attention to alignment, squareness, and structural integrity during assembly to ensure a sturdy and stable chassis.

- Mounting Components:

– Once the chassis is assembled, begin mounting the various components onto the robot. This includes motors, wheels, weapon systems, electronics, and any other necessary hardware.

– Use appropriate mounting hardware and techniques to securely attach components to the chassis. Consider factors such as weight distribution, balance, and accessibility when positioning components.

- Wiring Electronics:

– Carefully plan and layout the wiring for the robot’s electronics system, including motors, controllers, kill switch, and power distribution.

– Use high-quality silicon wiring, connectors, and insulation to ensure reliable electrical connections and minimize the risk of short circuits or electrical interference.

– Follow wiring diagrams and schematics to route and connect wires neatly and efficiently, avoiding tangles or crossings that could lead to problems during operation.

- Integrating the Control System:

– Install and configure the control system components, such as the radio receiver, transmitter, and BEC, according to the manufacturer’s instructions.

– Test the functionality of the control system to ensure that all components are working properly and responding as expected.

– Fine-tune control settings and calibration parameters to optimize performance and responsiveness during operation.

- Testing and Iteration:

– Conduct thorough testing of the robot’s mechanical, electrical, and control systems to identify any issues or deficiencies.

– Iterate on the design and construction as needed based on testing feedback, making adjustments to address performance issues, improve reliability, and optimize functionality.

– Test the robot in controlled environments, such as a practice arena or testing grounds, to simulate competition conditions and refine driving skills and strategies.

- Attention to Detail and Quality Craftsmanship:

– Throughout the construction process, emphasize the importance of attention to detail and quality craftsmanship.

– Take the time to double-check measurements, alignments, and connections to ensure accuracy and precision in every aspect of the build.

– Pay close attention to finish work, such as painting, polishing, or surface treatment, to enhance the appearance and durability of the robot.

By following these steps and emphasizing attention to detail and quality craftsmanship, the team can build a combat robot that is not only mechanically sound and electrically reliable but also visually impressive and competitively capable in the arena.