The Essence of Team Roles in Combat Robotics

Table of Contents

Team Roles and Responsibilities in Combat Robotics

Assigning roles and responsibilities within a combat robotics team in India is essential for maximizing efficiency and effectiveness. Here’s how to define roles and distribute responsibilities among team members:

- Team Leader/Team Managers: The team leader/team manager serves as the primary point of contact and decision-maker for the Team. They are responsible for coordinating team activities, setting goals and priorities, managing resources, and ensuring that the project stays on track. Team Leaders/Managers also have responsibilites to take care of funds and proper Bugeting. They also acts as a liaison between the team and external stakeholders, such as competition organizers or sponsors.

- Builders and Designers Team: The builders and designers are responsible for constructing the physical components of the robot, including the chassis, weapon system, and armor. They work closely with team to bring the robot’s specifications to life, using their skills in fabrication, machining, assembly and Maintainance of Robots.

- Drivers Team: The drivers are sole responsible for piloting the robot during competitions. They must have excellent hand-eye coordination, quick reflexes, and a deep understanding of the robot’s capabilities and limitations. The driver practices extensively to master the robot’s controls and maneuvering techniques, allowing them to execute the team’s strategy effectively in the heat of battle.

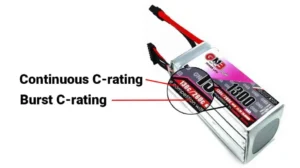

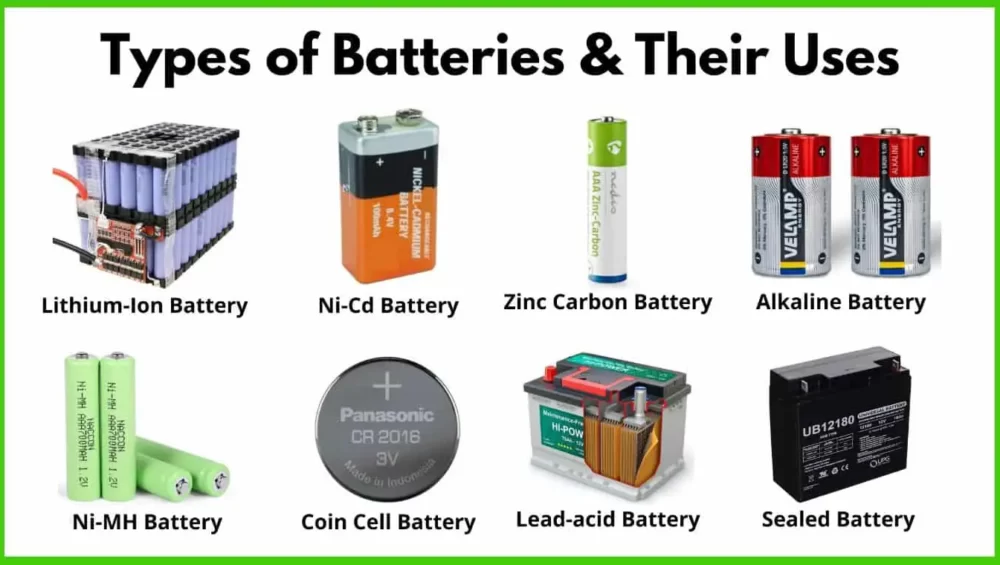

- Electronics Engineer’s Team: The electronics engineer’s are responsible for designing, assembling, and troubleshooting the robot’s electrical and electronic systems. This includes components such as motors, Kill-switches, controllers, and wiring. The electronics engineers ensures that the robot’s electronics are reliable, responsive, and optimized for performance.

- Social Media Team: The social media Team is responsible for developing the posts, videos, Vlogs, Blogs of events and Day to day updates to social media handles and promotion of team. Which generates awareness and imoprtant for gabbing sponsorships.

By defining clear roles and responsibilities within the combat robotics team, each member can focus on their areas of expertise, leading to a more efficient and cohesive project. Effective communication, collaboration, and coordination among team members are essential for success in building and competing with combat robots in India.

Click Here to explore our products.